- Unlimited width and width

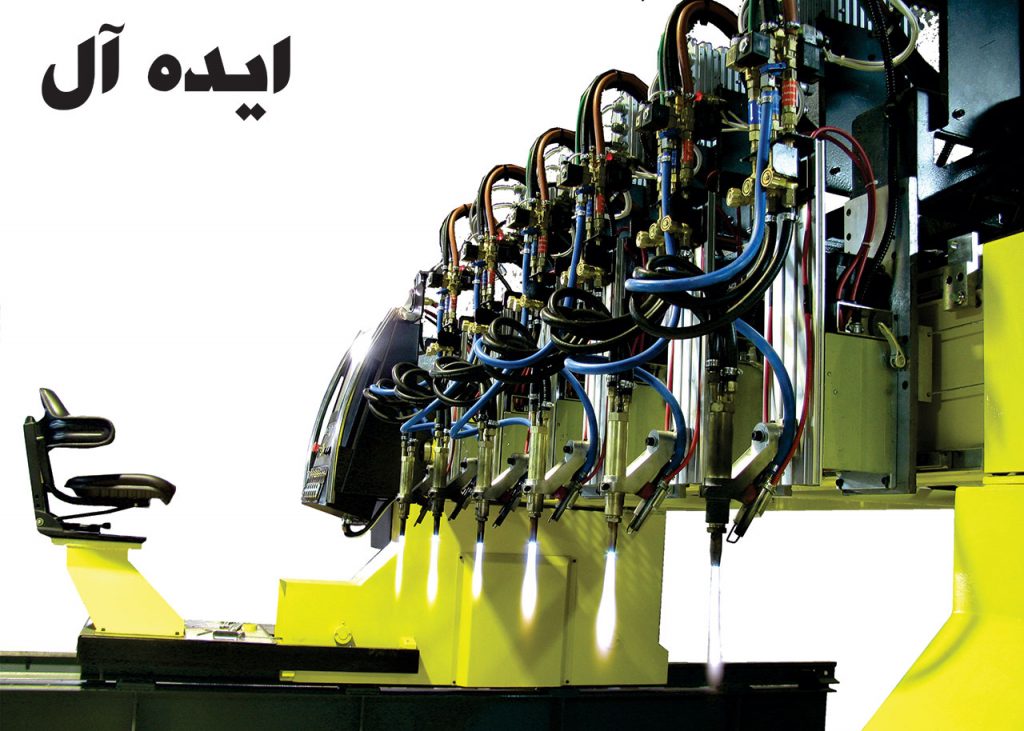

- With the ability to install different types of options

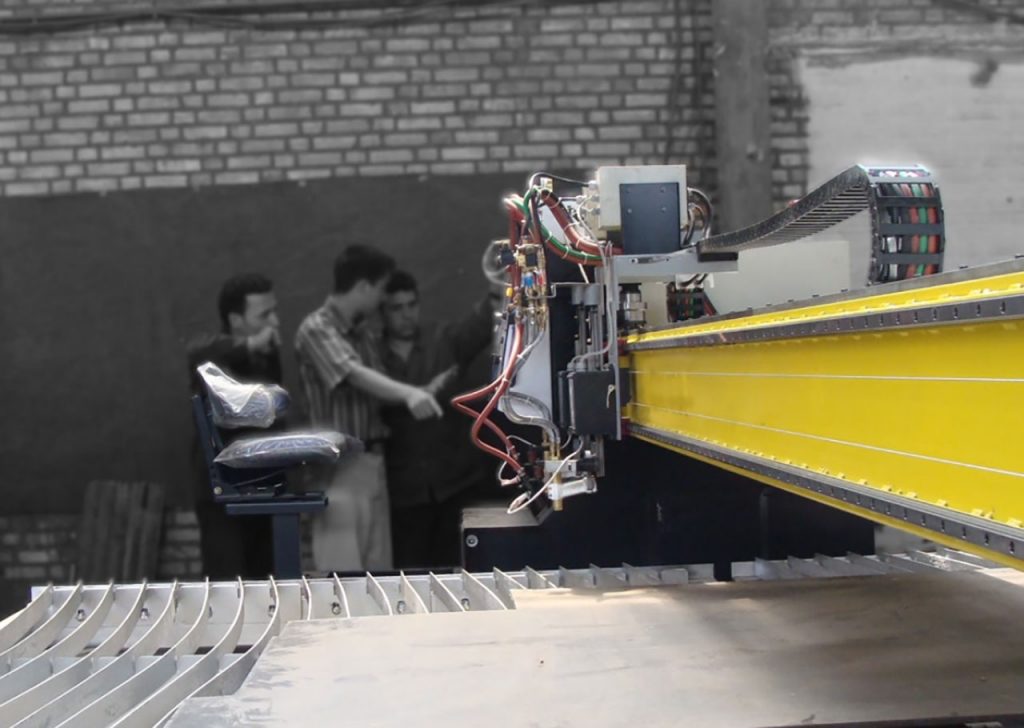

- Suitable for heavy and heavy work

- ergonomic design

| Technical Specifications for Plasma/oxyfuel Cutting Machine model : Heavy Duty | |

| Cnc controller | SmartCNC

Advanced IPC Rugged Fan-Less , dust proof IP Touch-Screen 15” 1. Touch panel with dust-proof control panel Ergonomic design 2. Integrated control system with equipment and peripherals No need for sophisticated and extra control outside the CNC 3. Operator’s prompt access to various operating systems and applications without complexity 4. Ability to run the program in a demo with a laser or a camera, and measure the size of the piece* 5. Workpiece calibration and tools using laser pointer or optics camera system 6. Simultaneous implementation of engraving, spinning and cutting tools in one piece and with a program automatically, producing complex and complete parts in one step. 7. Ability to expand, upgrade and add new features in the future 8. Capacity of pipe fitting and profiling (4 axes) 9. Ability to install additional tools, drills, markers and 10. Increase the life of plasma and oxy fuel components with special cycles* 11. Profiles for different types of sheets, call settings simply 12. Different settings for contours* 13. Industrial Parameters Library Parametric 14. File transfer via FTP-Server as a direct connection to download work programs* 15. 15. Registering system performance in general, project, and current status, including general information about the operation of the device and the system’s on-time and standby times.* 16. 16. Full network capability, access control panel of the engineering and management system to see the status of work*

|

| File format

|

DXF , G-Code |

| Supported processes with tools for switching

|

Plasma Cutting

OxyFuel Cutting *Marking , *Drilling |

| Longitudinal motion course

|

6200mm up to 24000mm |

| Crossing Course

|

2100mm up to 5400mm |

| The number of automatic plasma head

|

1 up to 2 Cutting Head |

| Number of oxyfuel head

|

1 up to 4 cutting head |

| Makring Head

|

1 Makring Head |

| Drilling Head

|

1 Drilling Head |

| Triggering system

|

Digital AC Servo + Planetary GearBox

Dual Drive for longitudinal Axis Delta Servo System Apex-Dynamic Low-Backlash Gear

|

| Longitudinal motion guide

|

Precision Linear Guide TBI Taiwan |

| Crossing Guide

|

Precision Linear Guide TBI Taiwan |

| Speed of movement

|

12.000 mm /min |

| Longitudinal and transverse impeller system

|

Precision Rack & Pinion

Made in Germany |

| Lateral / transverse actuation system | Zero-Backlash (0.0 mm) |

| Longitudinal and transverse movement accuracy | 0.1 mm |

| Plasma height control system | THC with Collision Protection |

| Initial ignition system | IHS |

| oxy Fuel Height Control System

|

CNC Controlled THC Sensor |

| Maximum Final Tolerance of the Production Piece | +- 0.2 mm |

| input voltage | 210 ~ 230V Single-Phase |

| Power consumption current (without unit of plasma) | Average 4A – Peak 15A |

| Permissible ambient working temperature | 0 .. 40 degree |

| THC plasma cutting | |

| head width | 150 mm |

| The suffering of plasma cutting | 0.5mm up to 160mm

(depend on Plasma Unit) |

| Standard equipment | Initial automatic spacing at first cutting, rising at the end of the cutting

Head of plasma rise at the end of the cutting and when moving fast, avoid collisions with cut pieces while moving fast Turbo protection against 3-D mechanical collision |

| Automatic sheet level detection | 150mm |

| The accuracy of the height control system | 0.5mm up to 160mm

(depend on Plasma Unit) |

| Controls the height of the plasma | CNC –Controlled THC

Automatic Corner Detection Automatic Pierce – Cut Height Automatic Torch Raise Stop on Collision |

| Automatic movement course | 200mm |

| Maximum plasma cutting speed | Max 8,000 mm/min |

| Oxy fuel THC | |

| head width | 150mm |

| Oxyfuel system | Koike Japan

B.O.C nozzle Parker Valves |

| Standard equipment | Initial automatic spacing at first cutting, rising at the end of the cutting

Head of plasma rise at the end of the cutting and when moving fast, avoid collisions with cut pieces while moving fast Turbo protection against 3-D mechanical collision |

| Automatic movement course | 200mm |

| Torch installation course | 200mm |

| Maximum oxyfuel cutting thickness | 300mm |

| Possibilities | Automatic Torch UP after Cutting

Automatic Height Adjust Automatic Torch Down before Cutting |

| oxy Fuel Height Control | CNC Controlled THC |

| Marking | |

| Maximum Marking speed | 2000 mm/min |

| Adjustable depth of engraving | 0.1mm up to 0.5 mm |

| Drilling | |

| Max diameter drilling drill | 10mm |

| Maximum drilling depth | 20mm |

| Tube cutting and profiles | |

| Pipe diameter diaper | 50mm up to 500mm |

| length of the pipe | 200mm up to 6000mm |

| Tube weight | Up to 4000 Kg |

| Adjustable base number | 3 Adjustable for

Pipe Diameter Locking |

| Supported Processes | Plasma Cutting

OxyFuel Cutting |